Success Stories

Kurt Brinson of B&B Gear and Machine Co. describes how the Load & Go saves his shop time and money in the manufacturing process.

Mike Budde improved his production output by implementing the Load & Go VBX-160 in his shop

Mike Grossi rates the Load & Go RC a 5/5 in this in-depth machining review.

See how Gilco Manufacturing Inc. increased their production and reduced downtime with Automation Within Reach. Automating machine-tending for their Haas VF-2SS CNC mill, allowing them to run multiple jobs consecutively.

Facing labor shortages, Northern Kentucky Machining (NKM) needed a solution to keep up with growing demand. In this exclusive interview, NKM shares how integrating the RC from AWR Flex Series into their operations was not only seamless—but transformative.

Customer Success Story: RAM Precision Industries

RAM Precision Industries was faced with the same challenges many other manufacturers are today which is to do more with less. Learn how they overcame these challenges with Automation Within Reach.

Read More

Prototyping is the Path from Tooling to Production Work

As a new owner takes over a tooling shop, he must balance the company’s foundation with his goal of expanding the shop’s capacity to also take on production work.

Read More

Success Story: Octane Workholding

Octane Workholding faced significant challenges that hindered their ability to meet customer demands and maintain competitive pricing. These challenges included bottlenecks, inefficiency, and a shortage of qualified labor for programming and machine tending.

Read More

Exigo Manufacturing's Success Story

Like many other manufacturers, Exigo faced the challenge of a workforce shortage. Struggling to find skilled laborers, they decided to pursue an automation solution. They were hesitant about the ease of use compared to understanding how machines operate.

Read More

Dimension Machine Increases Production

Dimension Machine LLC experienced a fundamental shift in its changeover operations and manufacturing capacity. The AWR Flex Series DC-2 automation system eliminated this constraint—requiring minimal changeover time while enabling more frequent part transitions.

Read More

Custom Automation: Reduce Cycle Time by 25%

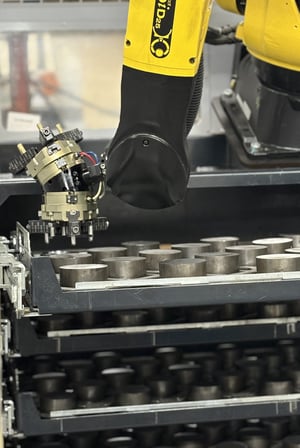

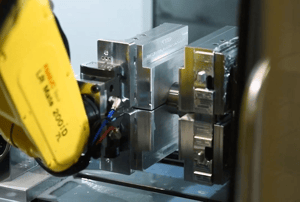

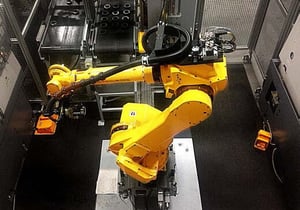

KitchenAid wanted to replace two aging CNC vertical milling machines with a solution that was faster, more reliable and met their quality of standards. Gosiger Automation designed and built a turnkey machining solution incorporating two Fanuc Robots and two independent servo-controlled driven drill heads.

Read More

A Michigan Manufacturer's Successful Automation Story

A small Michigan job shop struggled to maintain production and keep products in stock, and turned to AWR's simple, standard mill tending automation system. Learn how the company doubled its profit sharing in the first year.

Read More

Custom Automation: Fast ROI Convinces Versatile CNC Shop

Glacier Tool & Die explored automating its process with machine tending robotics to load and unload parts, ensuring competitive capability in its shop. Gosiger Automation integrated the machine tending robot and part feeder into the system, improving productivity.

Read More

How Robotic Helps a CNC Machine Shop Produce 47% More Parts-Per-Hour

By integrating a robotic tending cell to manage two lathes, Dimension Machine Company increased production efficiency—achieving nearly double the output on one part family and producing 47% more parts per hour.

Read More

Custom Automation: First Venture Into Automation

Hy-Tech Machine Inc. struggled to find qualified laborers while existing workers were tied up with repetitive tasks, like loading and unloading parts. Discover how the company integrated a custom CNC machine tending automation system to overcome its challenges.

Custom Automation: Small Town CNC Shop Is a Big User of Automation

Learn how a small town CNC shop like, Miller Precision Mfg. Industries, Inc., transformed its operations with advanced automation when it struggled to find skilled machinists and working with heavy workpieces.

Read More

Custom Automation: Robotics Automation Cell Cuts Cycle Time in Half

A custom robotic cell helped SEW-EURODRIVE reduce production time by 50%. See how it delivered consistent accuracy while streamlining the entire process.

Custom Automation: Robotic Cell Increases Productivity by 200%

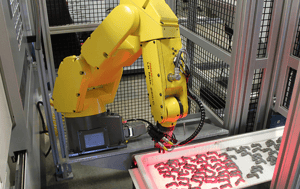

Hypertherm Inc., analyzed its current production method to identify opportunities for streamlining operations and maximizing ROI. Explore how machine tending automation increased output and reduced waste.

Read More

Custom Automation: Robotic Automation Reduces 40-Minute Part Production to Less Than 5 Minutes

Faced with industry demands for innovation, Northeast Tool implemented a robotic machining and inspection system that dramatically improved throughput, cost savings, and positioned the company for future market opportunities.

Read MoreHow Robotic Machine Tending Makes Automation Possible for any CNC Shop

This whitepaper delves into the several facets of machine tending that automation can improve as well as a few common misconceptions that would hinder one's consideration of robotic automation.