Custom Automation Solution

Reduces Cycle Time by 25%

and sometimes it's easy to dismiss an application as too simple to warrant robotic automation.

Recipe for Success

SITUATION

KitchenAid wanted to replace two aging CNC vertical milling machines with a solution that was faster, more reliable and met their quality of standards.

SOLUTION

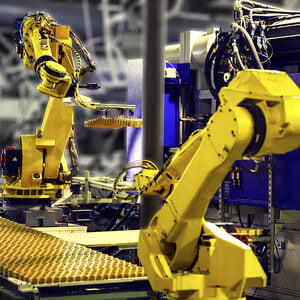

Gosiger Automation designed and built a turnkey machining solution incorporating two Fanuc robots and two independent servo-controlled driven drill heads served by inbound and outbound part conveyors.

RESULTS

Production rates improved by 25% and labor costs reduced.

For the KitchenAid Division of Whirlpool Corporation, machining a center hole and facing cut on the top of beaters and dough hooks for its iconic countertop mixer had long been managed by hand loading sets of four parts, one at a time, into CNC machine tools that were now nearing the end of their useful lives.

A logical approach when seeking replacement equipment is to look for new machines that would effectively replicate the existing process. However, when you’re making a product known since 1918 for its exceptional performance and durability, but are faced with today’s rising operational costs, it’s important to consider options that could improve productivity while maintaining product quality.

That was the mindset for Engineering Technician Doug Frazier and his team as they sent out their RFQ to a number of potential suppliers. “We’d worked with some of these companies in the past and others were new to us,” Doug explained. “We looked at several standard and custom CNC machines that could reliably deliver six-second or better cycle times.”

“What intrigued us about the proposal from Gosiger Automation was the inclusion of a robot arm for loading and unloading the parts integrated into a custom machining center. They also felt this would beat our cycle time requirement and it has. In the end it was the best combination of performance, quality and initial cost. It also fit into our plans to integrate this work station with future automation projects.”

The solution Gosiger Automation proposed was a self-contained, ergonomic workstation that houses a Fanuc LR-Mate 200iD six-axis industrial robot and two independent, servo motor-powered drill heads, along with coolant and chip management systems, all housed within a safety enclosure. An incoming conveyor for raw parts and an outgoing conveyor for completed parts service the workstation. The high-speed robots have a seven kg payload capacity, 717mm horizontal reach and are IP67 rated.

An auxiliary axis of the robot advances and retracts each drill head to enable simple adjustments of the drill depth, feed rates and speeds. The two 10,000 RPM rated drill units each have their own AC motor drives, are equipped with HSK-C 32 tool holders and include through-spindle coolant capability. An automatic ejector system discharges completed parts onto the outgoing, dual lane conveyor.

In operation, the robot picks up a raw part from the inbound conveyor and loads one of the two independent drill head fixtures. While that part is being machined the robot loads the second drill head. Once the machining process is complete, the part is ejected onto the outgoing conveyor and from there into a repository. During the machining process both flood and through spindle coolant evacuates chips and prolongs tool life.

The entire system is controlled through a Fanuc R-30iB Mate controller unit equipped with an additional option for the auxiliary axes. The machine operators use an HMI (Human Machine Interface) equipped with custom screens to simplify system operation.

According to Frazier, “This new work cell improves cycle time by 25% largely because the previous loading process required more operator time and dexterity. Now the operator simply places the parts into a vibratory conveyor and the Fanuc robot arm loads them into the fixture. Plus, having two drill stations means that while one part is being machined another is loaded into the second fixture.”

“We had a lot of changes going on in the plant when we started this project and Gosiger is a new supplier for us. These two things could have easily derailed the process, but everyone here and on the Gosiger team worked together to resolve the issues that always come up when working with custom equipment. Based on this experience we plan to work with Gosiger Automation on future projects.”

Explore Our CNC Automation Solutions

AWR provides comprehensive machine tending automation solutions for CNC lathe and mill operations. These CNC machine tending systems maximize productivity while maintaining the highest quality of standards, featuring unmatched performance and reliability.

In today’s competitive manufacturing landscape, maximizing productivity and maintaining top-tier quality is essential. The AWR Flex Series provides comprehensive automation solutions designed specifically for CNC lathe and mill operations. Our systems address the challenges of manual processes, offering seamless integration, increased throughput, and consistent part quality.

Read More

Boost efficiency and minimize downtime with Automation Within Reach's pre-engineered CNC machine-tending solutions designed for rapid implementation and maximum productivity. The Plus Series offers single—or dual-machine operation, custom end-of-arm tooling (EOAT), and three-cell options, Drawer, Conveyor, and Pallet, to fit your unique needs.

Read More

Our strength lies in eliminating all customer part touches in a component manufacturing process. We design, build, and test your system to ensure your project meets your expectations. Custom automation integration removes more tedious labor, increases robot and machine utilization, reduces scrap, and lowers the per-part price of the manufactured component.

Read More