Technology

AWR delivers advanced CNC automation technology built for proven reliability and straightforward, high-precision performance that reduces downtime, increases throughput, and accelerates your return on investment. Discover the technology that powers dependable automation for CNC machine tending.

-

All

-

DC

-

RCX

Discover the details

Electric Part HandlingElectric Control. Consistent Results.

AWR’s electric grippers deliver consistent, stable CNC machine tending with precise three‑finger gripping and fast, tool‑less changeovers. Built for high-mix shops, it provides reliable, adaptable automation.Discover the details

AWR’s electric grippers deliver consistent, stable CNC machine tending with precise three‑finger gripping and fast, tool‑less changeovers. Built for high-mix shops, it provides reliable, adaptable automation.Discover the details

See the benefits

QuickTouch HMISmart, Simple, and Scalable.

Our user-friendly interface makes CNC machine tending automation accessible and intuitive. Operators can manage complex tasks without coding experience.See the benefits

Our user-friendly interface makes CNC machine tending automation accessible and intuitive. Operators can manage complex tasks without coding experience.See the benefits

Explore the solution

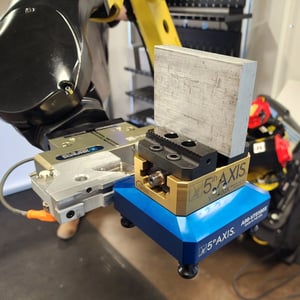

RCX PalletAutomate Pallet Transfers with Ease.

RCX Pallet enables efficient loading and unloading of pallets, reducing operator intervention and boosting productivity in robotic machine tending workflows.Explore the solution

RCX Pallet enables efficient loading and unloading of pallets, reducing operator intervention and boosting productivity in robotic machine tending workflows.Explore the solution

See how it works

RCX MultiGrip™One Robot, Multiple Grips.

The Flex Series RCX Multigrip™ eliminates the need for manual changeovers. With its versatile gripping system, you can efficiently automate high-mix, low-volume productions.See how it works

The Flex Series RCX Multigrip™ eliminates the need for manual changeovers. With its versatile gripping system, you can efficiently automate high-mix, low-volume productions.See how it works