A Michigan job shop struggled to maintain production and keep popular products in stock, leading it to seek a simple automation solution for its manufacturing process.

The company implemented an AWR machine tending robot as a standalone cell, requiring additional training for operators who initially expected the system to run unattended.

A small Michigan-based manufacturing company, known for producing the highest-quality products in the world, serves DIYers and small businesses in the outdoors industry.

Struggling to maintain production and keep its most popular products on the shelf, the Michigan job shop began extensive research for a CNC automation solution. Needing technology that was easy to manage and operate, found a simple automation solution that didn't require an automation expert.

Initially, the CNC machinery and automation were not blended for the current production line, and instead, the AWR machine tending robot was introduced as a "standalone" cell. At first, there was a misconception that the robot unit would run without an operator. Therefore, training the shop floor about the required maintenance and procedures to operate the automation unit took time compared to their current understanding of CNC machining practices without automation.

Once fully integrated, the AWR machine tending automation cell increased production by doubling its profit sharing in the initial year. For instance, manually loading parts is quicker than the automation system. However, the machine tending robotic unit runs continuously, and its output equates to manually loading machines with two operators at the end of the week.

Overall, purchasing an automated CNC robotics unit has increased the company's ability to manufacture bulk orders of its high-demand products, while laborers can focus on customized parts. Beyond improving efficiency and cutting lead times, the numbers speak for themselves—"just for the automation. Our ROI was achieved in 9 months." The results led the company to purchase a second machine tending robot and build another cell to its operations. Lastly, the company advises, "Do not sacrifice quality to save a small percentage on the total project cost of implementation,". The company's commitment to quality over cost savings became its foundation for sustained growth and competitive advantage.

Explore Our CNC Automation Solutions

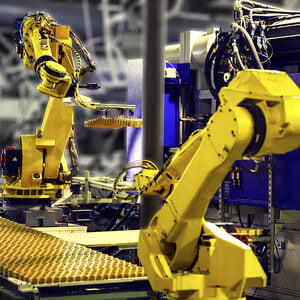

AWR provides comprehensive machine tending automation solutions for CNC lathe and mill operations. These CNC machine tending systems maximize productivity while maintaining the highest quality of standards, featuring unmatched performance and reliability.

In today’s competitive manufacturing landscape, maximizing productivity and maintaining top-tier quality is essential. The AWR Flex Series provides comprehensive automation solutions designed specifically for CNC lathe and mill operations. Our systems address the challenges of manual processes, offering seamless integration, increased throughput, and consistent part quality.

Read More

Boost efficiency and minimize downtime with Automation Within Reach's pre-engineered CNC machine-tending solutions designed for rapid implementation and maximum productivity. The Plus Series offers single—or dual-machine operation, custom end-of-arm tooling (EOAT), and three-cell options, Drawer, Conveyor, and Pallet, to fit your unique needs.

Read More

Our strength lies in eliminating all customer part touches in a component manufacturing process. We design, build, and test your system to ensure your project meets your expectations. Custom automation integration removes more tedious labor, increases robot and machine utilization, reduces scrap, and lowers the per-part price of the manufactured component.

Read MoreReady to Transform Your CNC Operations?

Download the PDF version to take this case study with you.

Or connect with our automation experts to explore your specific CNC machine tending opportunities.