There are as many reasons to explore manufacturing automation as there are CNC machine shop owners. For Rusty Arant of family-owned Northeast Tool, located in Matthews, NC, the trigger was a statement

he heard at a 2013 customer/supplier conference.

“The speaker said, ‘If you are not a progressive company that is willing to automate, you may not be here next year,’” Rusty said. That was a wakeup call for the then 50-year-old precision manufacturing

company.

“We’d been considering ways to improve our workflow, but hadn’t really looked into using robots to automate our machining processes. We already had some robotic welding stations, but that was the extent of

our manufacturing automation,” he said.

Northeast Tool’s 62 employees produce about 2,000 unique parts each year in quantities ranging from one-offs to 40,000pieces. Their customers include companies in transportation, aerospace, medical, defense and energy industries. Their annual volume is $12 million.

One of the high volume parts they produce is a series of aluminum end caps for carbon fiber CNG (compressed natural gas) tanks. These “return to base” tanks carry fuel for busses, trucks and other vehicles that traditionally run on diesel or gasoline.

CNG is a greener, cleaner burning alternative fuel that creates less pollution. When Rusty took a close look at the manufacturing process for these parts, he identified it as an opportunity to convert the existing approach to robotic automation.

Value Streaming & Lean Principles

Rusty documented every step of the existing manufacturing process from raw materials, through machining, inspection and preparation for shipping. “I decided to take the approach that everything we were currently doing to make these parts was wrong,” Rusty said. “This helped me look at the job with fresh eyes. Instead of simply trying to improve the process we already had, we rethought our entire approach to see how we could make these parts much more efficiently.”

The existing process began with receipt of bar stock that Northeast Tool would saw to size, load into the first machine tool to rough, turn one end and then set aside for batching. When a batch of parts was ready, each part would be individually loaded into additional machines for further processing, which included a polishing machine to achieve the required surface finish. Because of all of the handling in and out of machines, the parts often had to be re-polished to meet specifications.

What Rusty discovered was that each part traveled the equivalent of one mile throughout his facility from start to finish. The entire process required three CNC lathes, two milling operations, polishing, washing and inspections after each operation. Throughout this journey, the part was touched by more than 15 people over two and one-half shifts. These touches included sawing and stacking bar stock on pallets, machining, counting, batching, washing, inspecting and shipping. Recognizing that every touch adds cost to a part, Rusty knew he needed a less hands-on process.

A Turnkey Solution

Rusty began talking to suppliers to identify a company that had the capability to combine machining, inspection and automation. “I wanted a system that would integrate everything from raw materials to finished parts and could be attended by a single machine operator,” he said.

Not only is this a huge time savings, it also frees up considerable floor space that was occupied by the additional 14 people, tools and working space the former system required. “I then had the ability to add more machines to expand our capacity and repurpose our people to other jobs,” Rusty said.

Gosiger Automation System

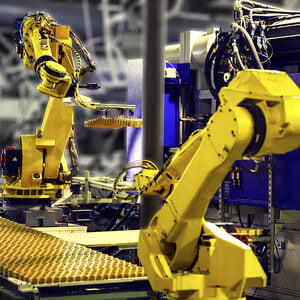

The automation system consists of one Fanuc R-2000iB/165F six-axis industrial robot positioned in the center of three Okuma LB-3000EX-MY lathes arranged in a semi-circle. A floor-mounted pallet locator positions a pallet holding workpieces delivered by a lift truck. The family of parts consists of 17 distinct end caps made from blanks that range in size from 4” in diameter by 3” long, to 8” in diameter by 8” long.

Rethinking the process from raw material onward led to replacing the raw bar stock that Northeast Tool originally sawed into part lengths, with precut bars bearing part identification codes. The robot employs an end-of-arm-tool mounted iRVision system to confirm the part identification codes and locate the parts for pickup.

“I talked to a number of suppliers but didn’t find what I was looking for until Okuma dealer Morris South brought in Gosiger Automation,” Rusty said. “They listened to what I wanted to achieve and came back with a plan that checked all of my boxes.”

“As a result, we now make aluminum CNG tank end caps that previously took 39 minutes, 21 seconds to complete in just 4 minutes, 51 seconds from raw stock to out the door.”

An end-of-arm three-jaw O.D. gripper system grips the workpiece on the outside shank diameter for loading and unloading the lathes’ as well as placing and removing parts for post-process inspection on a Coordinate Measuring Machine (CMM).

All programs for the 17 part numbers reside in the machine tool and are called up by the automation system based on the next part to be processed. In operation, a part is located by the robot using the vision system to identify the 2D bar code, then loaded into the first machine tool that performs rough machining. The robot unloads the workpiece from the first machine and loads it into the second Okuma lathe where the front side is machined. The third lathe performs milling and second turning operations. Between operations, the robot flips parts as necessary based on the part program.

Post machining, the robot unloads the part from the third lathe and places it on a coordinate measuring machine for inspection.

Data from the CMM measurements are fed back into the machine tools to enable automatic tool offsets.

“This expansion will enable us to further automate our plant and provide much needed space for material storage. As well as improve our shipping and receiving functions. Our goal is to make every aspect of our business more efficient as we move into new markets.

“When you consider it, mankind has always made things by using some sort of hard tool to shape softer material,” Rusty continued. “We’re still doing that with tooling that’s harder than the materials we cut. Automating this process and integrating inspection to maintain tolerances takes it to the next level. Soon I see us combining automated machining with newer technologies like additive manufacturing, to make us even more productive. I’m glad we had that wakeup call to automate a few years ago and that we found a capable and easy to work with partner in Gosiger Automation.”

Explore Our CNC Automation Solutions

Maximize your CNC potential with AWR's comprehensive machine tending automation. Our automation systems eliminate production bottlenecks across lathe and mill operations, delivering consistent quality and reliability that drive manufacturing success.

The AWR Flex Series offers standard automation solutions designed to streamline production and reduce costs. Designed specifically for single CNC lathes and mills, our DC, RC, and RCX systems streamline machine loading and unloading operations, minimize costly downtime, and optimize skilled labor utilization—delivering the straightforward implementation and instant productivity gains that drive manufacturing success.

Read More

The Plus Series delivers automation without compromise—combining the speed of pre-engineered solutions with the precision of custom applications. Our proven Pallet, Drawer, and Conveyor options provide 80% complete automation foundations, enabling rapid implementation while maintaining the flexibility for specialized end-of-arm tooling that meets exacting manufacturing specifications.

Read More

When your production challenges demand solutions beyond standard automation, AWR's Custom Integration Solutions provide the engineering expertise to transform complexity into operational excellence. Our comprehensive approach addresses unique manufacturing requirements through fully tailored systems—designed, built, and tested to optimize multi-step processes and specialized applications—bringing smarter automation within reach.

Read More