With their employees having to waste time on tasks not befitting their skills, Hy-Tech Machine Inc. decided the answer was to add automation to their operation. Alongside Okuma, Gosiger designed a system that helped Hy-Tech get the most out of their people increasing efficiency and productivity.

Hy-Tech Machine Inc. struggled to find qualified laborers while existing workers were tied up with repetitive tasks, like loading and unloading parts.

![]()

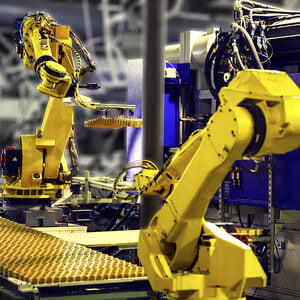

Integrated a CNC machine tending automation system with an Okuma Multus B300 and Fanuc M-20iA robot into its operations.

![]()

Accomplish lights-out manufacturing without adding headcount, while reducing cycle time from 32 minutes to 21 minutes on its largest volume part.

![]()

First Venture into Automation

Introducing robotic-based automation to a 90-year-old company that places a high value on the talents of its long-time employees was a big step for Bob Ober and Pittsburgh, PA-based Hy-Tech Machine Inc. “We have 60 hard-working employees performing turning, milling and grinding operations on 38 CNC machines,” Bob explains, “and they all do a great job.”

However it’s increasingly difficult to find qualified people to add to our staff. Meanwhile, our machine operators were bogged down with material handling, part loading and unloading and other tasks that were not the best use of their skills. So we decided to investigate automating some of these procedures.”

Hy-Tech produces a comprehensive line of impact wrenches and other industrial-grade pneumatic tools, as well as replacement parts for many other brands. One aspect of the manufacturing process involves a family of 11 critical impact hammer components that Bob considered a good candidate for automation. He turned to his long-time Okuma CNC machine dealer, Morris Great Lakes, for a solution.

Morris consultant John Rodgers recommended an Okuma Multus machining center and brought in Gosiger Automation, the authorized systems integrator for Okuma America, to design the robot-based system.

According to Mr. Ober:

“Adding this automation system was a big investment for a company of our size, so we had to make sure we worked with someone who would listen to what we needed and then come up with the right approach.

Gosiger Automation came through with a simple plan that combines the flexible and multifunctional Okuma Multus B-300 CNC machining center, with a Fanuc M-20iA six-axis industrial robot, and a fixtureless conveyor system. The steel slugs we machine sit on the incoming

conveyor and the robot uses a vision system to locate and then pick up and load the parts into the machining center. At the end of the cycle, the robot arm removes the part and places it on the outgoing conveyor.”

Gosiger Automation Explains Further

“We positioned the robot directly in front of the machining center while allowing the operator ergonomically correct access to the machine tool, and surrounded the robot work area with interlocked perimeter guards to ensure worker safety. Because of the amount of material removed from the part during the machining process, we equipped the robot with a dual gripping system to enable it to reliably handle the part both before and after each machining cycle.”

The Robotic Automation Works Like This:

As the Okuma lathe machines a part, the Fanuc robot uses its IRVision system to locate and pick up the next raw blank from the inbound parts conveyor for processing. The lathe’s end of cycle signal queues the robot to open the machine door, load a part blank in the lathe’s sub-spindle, unload the finished part from the main spindle, close the machine door and initiate a machine cycle start command.

For optimum efficiency the finished part is deposited on the outbound conveyor by the robot as the machine tool produces a new part, and the next raw blank is picked up and staged.

“Gosiger Automation spent the time to really understand our needs. They came up with a design that made sense and then took us every step of the way through parts runoff, installation and training. Both Gosiger and Morris have provided excellent support throughout.”

“The Multus has allowed us to reduce our cycle time from thirty-two minutes to twentyone minutes on our largest volume part, with similar savings being realized on all parts that we run through this machine. We currently have processed and proven sixteen different parts, with another twenty in engineering. One of the key benefits of this system is its flexibility.

I can run 50 – 500 pieces of any one of the 11 configurations in this family of parts and then quickly change over to another part by simply replacing the chuck and the robot gripper, and then calling up the

new program. All of the tooling resides inside the machining center’s automated tool changer, so we don’t have to worry about that aspect. I can even interrupt a part run to make a different part, and then resume the original run.”

“By adding this automated process we now have one machining center producing as many parts as we previously ran on three machines – and with no operator intervention. This ability to operate unattended allows us to run a “lights out” shift. So, for us, the benefit is greatly increased throughput, as opposed to simply reducing machining cycle time. What we’ve really done is eliminate a lot of dead time for our people so they can accomplish more, plus we have greater consistency and better quality parts. We’re now in the process of expanding the number of SKUs from the original 11 parts to 40, and looking forward to adding a second machining center installation.”

If you’re searching for ways to boost productivity, reduce labor cost, improve delivery times and compete more successfully, talk to Gosiger Automation. With over 90 years of machine tool experience, Gosiger has the expertise, experience and technology to make a single CNC machine or an entire factory more efficient and profitable.

Explore Our CNC Automation Solutions

Maximize your CNC potential with AWR's comprehensive machine tending automation. Our automation systems eliminate production bottlenecks across lathe and mill operations, delivering consistent quality and reliability that drive manufacturing success.

The AWR Flex Series offers standard automation solutions designed to streamline production and reduce costs. Designed specifically for single CNC lathes and mills, our DC, RC, and RCX systems streamline machine loading and unloading operations, minimize costly downtime, and optimize skilled labor utilization—delivering the straightforward implementation and instant productivity gains that drive manufacturing success.

Read More

The Plus Series delivers automation without compromise—combining the speed of pre-engineered solutions with the precision of custom applications. Our proven Pallet, Drawer, and Conveyor options provide 80% complete automation foundations, enabling rapid implementation while maintaining the flexibility for specialized end-of-arm tooling that meets exacting manufacturing specifications.

Read More

When your production challenges demand solutions beyond standard automation, AWR's Custom Integration Solutions provide the engineering expertise to transform complexity into operational excellence. Our comprehensive approach addresses unique manufacturing requirements through fully tailored systems—designed, built, and tested to optimize multi-step processes and specialized applications—bringing smarter automation within reach.

Read More